Several steps are necessary before the extruded profile can be used as a constructional component with the intended strength. The further processing includes stretching, heat treatment, sawing, bending, and machining. Magnesium has very good machining abilities (sawing, drilling, turning, milling) compared to other metal, The specific cutting power is low, the chips are short, and the surface is excellent. Short cut profile segments for use as levelers or engine housing are simple to build and offer a good alternative to cast components.

epending on the alloy, magnesium profiles are hard to bend at room temperature. The hexagonal crystal structure limits the cold deformation, but elevated temperatures increase the deformation behavior significantly. Only AZ31 profiles may be bent with wide radii at ambient temperature; smaller radii and other alloys require higher deformation temperatures. Profiles can be joined among themselves, or with any cast or forged part. The most widely used joining methods are screwing, staking, gluing, MIG welding and TIG welding, as well as laser welding. Since magnesium has a high electron negativity, sufficient insulation us needed.

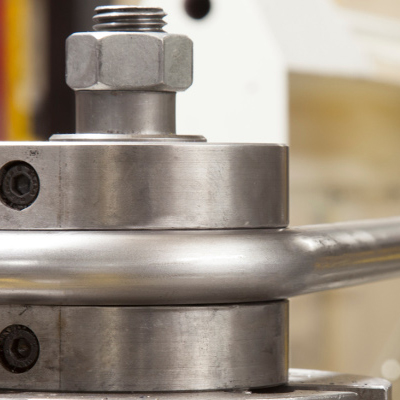

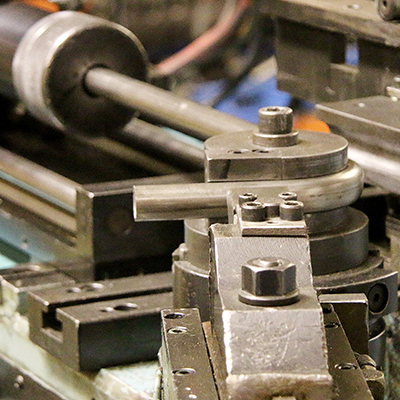

Bending technology at Licht

Bending magnesium profiles.

Licht has two different bending machines in house. We use these machines to bend various magnesium profiles for our customers. We are able to bend both simple and complex shapes, in 2D and 3D. Our newest CNC bending machine can perform stretch and roll bending in 2D and 3D. With this method we can bend your magnesium profiles in almost any shape. The 3D bending is preferably done in a single process step, making further operations redundant.

Licht bends simple and complex magnesium profiles for various industries, such as the aircraft and aviation industry, automotive industry, and medical industry.

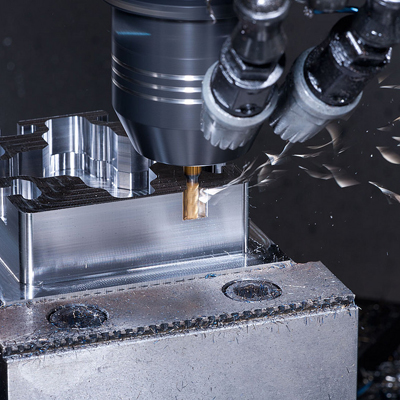

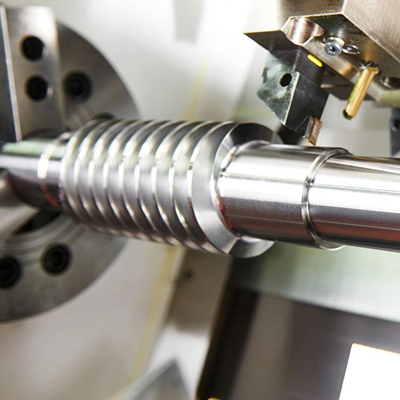

CNC machining of magnesium AZ31

For many years Licht has specialised in machining parts in magnesium AZ31. We mainly produce prototypes, special parts and small quantity series.

We can offer 5-axis, 3-axis and advanced turning operations. All operations are carried out in-house in our advanced machine shop.

Preferable the parts are machines from hot rolled AZ31B blocks, but the magnesium blocks can also be produced in our own foundy and here we can supply standard casting alloys such as magnesium AZ91 and magnesium AM60.

welding

Magnesium possesses properties that make welding it different from the welding of steels. Many of these are the same as for aluminum. These are:

- Magnesium oxide surface coating, which increases with an increase in temperature.

- High thermal conductivity.

- Relatively high thermal expansion coefficient.

- Relatively low melting temperature.

- The absence of color change as temperature approaches the melting point.

- The normal metallurgical factors that apply to other metals apply to magnesium as well

We can do argon arc welding of complex shapes and friction stir welding of flat products.