Introduction

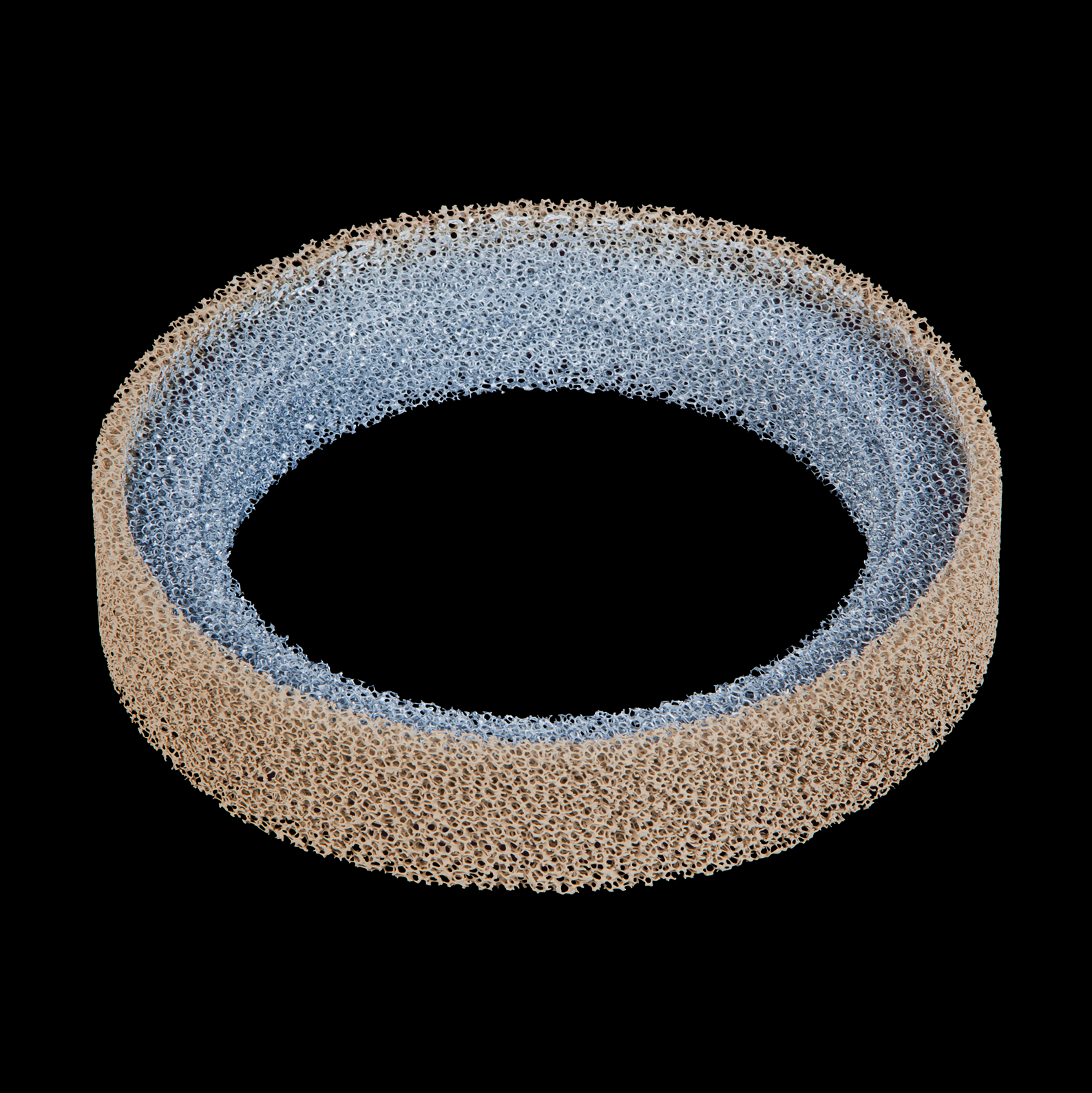

Aluminum foam can be manufactured applying a variety of methods including direct foaming of aluminum alloy melts and advanced metal powder processing. Complex-shaped foam components and 3D-shaped sandwich panels consisting of foam cores and aluminum face sheets can be produced. The application potential of these materials is discussed for various fields, namely light-weight construction, crash energy absorption and thermal or sound insulation. Various case studies are presented—a lifting arm for a lorry, a crash box for a car an impact energy absorber for a tram, a motor bracket for a car and a transverse beam for a machine. Ultra-light metal foams became an attractive research field both from the scientific and industrial applications view points. Closed-cell metal foams, in particular aluminum alloy (Al-alloy) ones can be used as lightweight, energy-absorption and damping structures in different industrial sectors, detaining an enormous potential when transportation is concerned. Aluminum foams are isotropic porous materials with several unusually properties, that make them especially suited for some applications. Due to their low densities between 0.3 g/cm3 and 0.8 g/cm3 the foams can float in water (in case of closed porosity). Foams exhibit a reduced conductivity for both heat and electricity. The strength is lower than conventional dense aluminum and declines with decreasing density. Foams are stable at temperatures up to the melting point. They are incombustible and non-toxic.

Aluminum foam can be manufactured applying a variety of methods including direct foaming of aluminum alloy melts and advanced metal powder processing. Complex-shaped foam components and 3D-shaped sandwich panels consisting of foam cores and aluminum face sheets can be produced. The application potential of these materials is discussed for various fields, namely light-weight construction, crash energy absorption and thermal or sound insulation. Various case studies are presented—a lifting arm for a lorry, a crash box for a car an impact energy absorber for a tram, a motor bracket for a car and a transverse beam for a machine. Ultra-light metal foams became an attractive research field both from the scientific and industrial applications view points. Closed-cell metal foams, in particular aluminum alloy (Al-alloy) ones can be used as lightweight, energy-absorption and damping structures in different industrial sectors, detaining an enormous potential when transportation is concerned. Aluminum foams are isotropic porous materials with several unusually properties, that make them especially suited for some applications. Due to their low densities between 0.3 g/cm3 and 0.8 g/cm3 the foams can float in water (in case of closed porosity). Foams exhibit a reduced conductivity for both heat and electricity. The strength is lower than conventional dense aluminum and declines with decreasing density. Foams are stable at temperatures up to the melting point. They are incombustible and non-toxic.

Characteristics:

- Low Density

- High Strength to Weight Ratio

- High Surface area to Volume Ratio

- isotropic load response

- controlled stress-strain Characteristics

- Can be Heat Treated

- Brazable

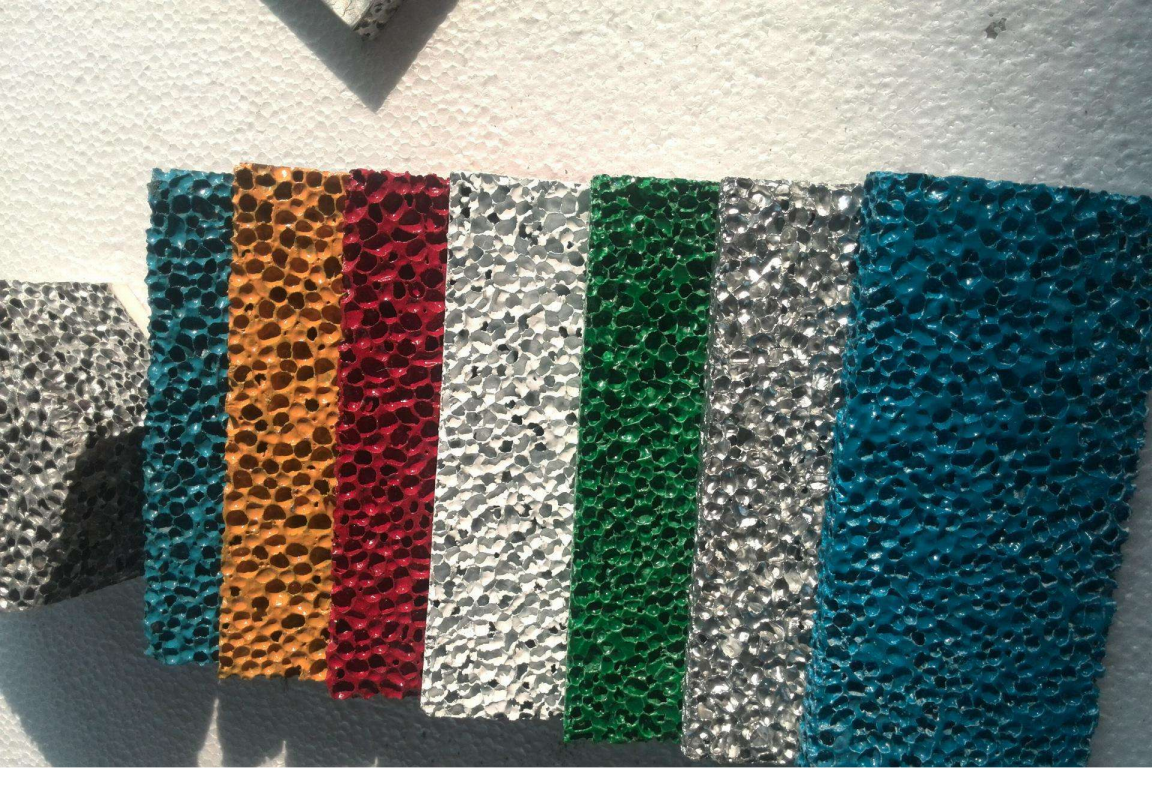

- Can be coated and plated

General Properties:

| Density Range | 3-12% |

| Max Compression | 70%+ |

| PPI Available | 5, 10, 20, 40 |

| Alloys | 6101*, 6061, 7075, 1100 |

Physical Characteristics of Duocel® Aluminum Foam* (8% Nominal Density 6101-T6):

| Compression Strength | 367 psi | (2.53 MPa) |

| Tensile Strength* | 180 psi | (1.24 MPa) |

| Shear Strength* | 190 psi | (1.31 MPa) |

| Modulus of Elasticity (Compression)* | 15 × 10 3 psi | (103.08 MPa) |

| Modulus of Elasticity (Tension)* | 14.6 × 10 3 psi | (101.84 MPa) |

| Shear Modulus | 2.9 × 10 4 psi | (199.95 MPa) |

| Vickers Pyramid Number | 35 HV | |

| Specific Heat | .214 BTU/lb-°F | (.895 J/g-C) |

| Bulk Thermal Conductivity | 3.4 BTU/ft-hr-F | (5.8 W/m-C) |

| Coefficient of Thermal Expansion (0-100°C) | 13.1 × 10 -6 in/in--F | (23.58 × 10 -6 m/m--C) |

| Bulk Resistivity | 2.84 × 10 -5 ohm - in | (7.2 × 10 -5 ohm - cm) |

| Melting Point | 1220°F | (660°C) |